Smart response to the increasing number of milking robots on dairy farms

Technological developments are moving fast in all areas of agriculture and dairy farming is no exception. For instance, more and more dairy farmers are switching to robotic milking. This shift requires a different approach not only from dairy farmers but also feed suppliers. You need to correctly analyse the milk data and farm management, and translate these into applicable solutions to support farmers so they get the most out of their milking robots and cows. In this way, you can stand out as a feed supplier and increase your value to your customers. To achieve this, field staff have to be trained to bring that added value to the farm.

As with conventional milking, a large part of the success of robot milking depends on an optimal ration with the right complementary concentrates. In order to improve results on robot farms, the focus is often on ration optimisation, improving chunk quality and making palatable pellets amongst other things. These are important of course, but certainly not the only way to improve results on a robot farm. Aspects like milking robot settings, barn layout and health status of the herd are just as important.

Thinking like a cow

When looking at robot milking and adjusting robot settings or barn conditions, we need to think from the cow's point of view. For example, when setting up the robot, what does a cow want to do after milking? She wants to drink, so you need to have a trough near the robot outlet. But the trough shouldn't be too close either, otherwise it will interfere with the outlet. Something else that's remarkably common and can have very negative consequences are protruding bolts or unevenness in the cow's walkway near the robot.

So there are many things around the robot that can determine the success of robotic milking. A field specialist with a well-trained eye can recognise these situations and advise farmers on how to improve conditions.

Analyse with the help of our Robot analyse program

To improve results on a robot farm, it's important to make the right analysis. Knowledge of the robot software is important and as is good data analysis. For this purpose, we use a programme that allows us to analyse the data from different brands of milking robots in the same way. This often leads to useful insights and helps determine the right settings.

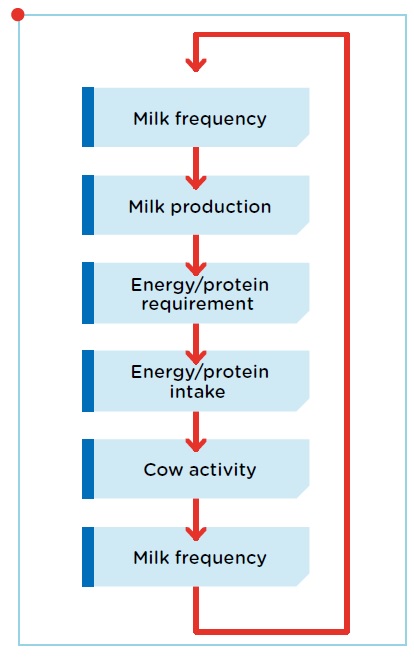

You can see in the analysis when the robot's admission settings have a major negative effect on the performance of cows. For example, if a cow that produces 40 kg of milk on average and after 40 days goes from a start-up setting to the standard lactation setting, and according to the robot's settings, is suddenly switched from 5 milkings to 2.5 milkings per day, the cow will react. It will be reluctant to come to the robot because they are constantly being rejected. This will decrease activity, reduce milk production and ultimately affect the farmer's technical and financial results.

The right advice on barn set-up and robot settings will help improve farm results and prevent problems.

Train your advisors to become a robot specialist

There are lots of other examples. At Koudijs, we can support you in training technical specialists in the proper supervision of robot farms and support them in further application. This includes all the different aspects of robotic milking, from barn layout and animal signals to software settings. With the right robotic milking support, you will help your customers move forward and be of greater added value on the farm. Interested in hearing more about our approach? Feel free to contact us.

Knowledge is key

In order to successfully advise on a dairy farm where milking robots are in use, it's essential to have knowledge of the relationship and interaction between:

Read the latest version of the Koudijs newsletter!

Read hereAbout the author

Thijs Hunink

Specialist Ruminants