Overcoming the challenges of organic poultry feed formulation

Organic farming is meant to benefit the general wellbeing of animals by mimicking a more natural life cycle. This includes improved housing, maximum density of hens, free range conditions and use of organic feeds. Applying these measures has implications for the productivity of the farm and even more so for the nutritional quality of the feed.

It's striking that there are far more organic laying poultry farms than broiler farms. For example, the market share of organic laying poultry farms in the Netherlands is approximately 10% compared to <0.7% for organic broiler farms. This is mainly because eggs are an important part of vegetarian diets and because people who eat organic food usually eat less meat. In addition, organic eggs are a cheaper source of protein than organically grown chicken meat.

Achieving optimum nutrient levels

Whether an organic farm is a broiler or a layer farm, it uses organic feeds produced with certified organic raw materials. And that’s where the big challenge lies.

The availability and composition of organic raw materials varies considerably, both regionally and worldwide. Incorporating safety margins for nutrients to compensate for these variations is not always a solution to meeting a farmer’s performance requirements. That’s why it’s essential to analyse the composition of every lot of raw materials.

Amino acid levels

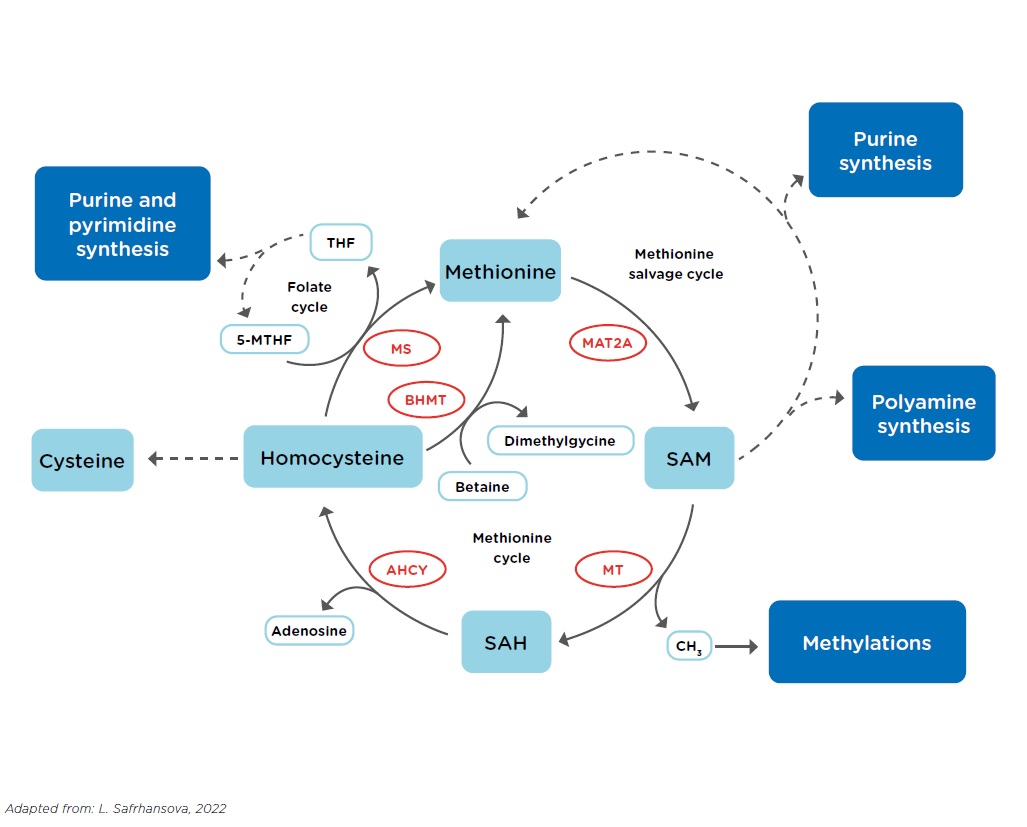

Amino acid profiles of commonly used raw materials, such as corn, wheat, barley, soybean, and sunflower seed, don’t meet the nutritional requirements that lead to the most efficient growth or egg production. These raw materials contain low levels of methionine. Optimal lysine levels in layer feed can be achieved by using a higher level of crude protein (ranging from 1 to 3% higher), despite the increased risk of unwanted bacterial overgrowth in the intestines. Young birds are an exception, since they require a higher protein level in their feed for better animal welfare and optimal growth. You cannot achieve this with only organic raw materials. It’s therefore possible to use a maximum of 5% conventional (non-GMO) raw materials for protein purposes. Even with increased protein, methionine is still lacking in feed by approximately 10%. Methionine donors such as betaine and choline are commonly used, but they have a limited impact. To compensate for this, Koudijs has developed a special approach for organic poultry farming which involves stimulating the different pathways for the re-methylation of homocysteine to methionine.

Enzymes in organic feed

Phytases are not allowed in organic feed production so you cannot reduce the use of inorganic phosphorus. Fortunately, NSP enzymes are allowed. The use of a multi NSP enzymes rather than single NSP enzymes is recommended to better reduce negative effects of non-starch polysaccharides.

Effect on egg weight

Despite not reaching the desired methionine level in layer feeds, you can hold the nutritional requirement for adult laying hens at a reasonable level with higher crude protein and with a slightly higher feed intake. Production will be good, but the combination of increased crude protein with a slightly higher feed intake results in heavier eggs. This leads to a faster deterioration of eggshell strength as the birds get older. A potential solution is to use organic palm oil since it’s a saturated oil. This means you can decrease linoleic acid by up to 14% in the feed which is normally present in oily cakes of raw materials such as sunflower cake and soybean cake. Reducing linoleic acid in the diet leads to a lower stimulation of egg weight.

Particle size

Another important issue for layers is maintaining a constant particle size distribution in the feed. Raw materials for organic feeds often come from different suppliers. Due to varying availability, this can affect their particle size and therefore the feed structure. In many cases, this means more fines in the feed which can impact the eating behaviour of the flock. This can lead to unwanted behaviour, such as decreased feed intake and other discomforts that can eventually result in problems with feather covering, feather pecking and non-uniform growth. Unfortunately, you cannot always prevent this lack of feed uniformity, but the use of different milling techniques and arseness can be of big help.

Broiler feed issues

In contrast to layers, different breeds of broilers are used for conventional and organic farming. However, you still need to manage daily weight gain in slow growing broilers, which are the accepted breeds for organic farming. This is due to their partly conventional gene pool. Techniques like withdrawing feed to control weight gain are not allowed. In the same way, light management is challenging because a minimum of 8 hours of darkness is mandatory.

Pelletized feed is allowed, but overeating, lack of size uniformity and uncontrolled overgrowth are potential risks. Feeding crumbles can reduce these risks by increasing satiation. Mash feeding is also an option, but this can result in selective feeding and de-mixing of the mash. This can again lead to uncontrolled growth and lack of size uniformity.

Methionine deficiency in organic poultry diets

In organic poultry production, where methionine supplementation is limited, optimising remethylation pathways is crucial to maintaining adequate methionine levels. Both the Methionine Synthase and Betaine-Homocysteine Methyltransferase pathways play essential roles, supported by the methionine salvage pathway and the serine-glycine-folate interconnections. Through strategic dietary adjustments and supplementation, it's possible to enhance these metabolic pathways, ensuring healthy growth and productivity in organic poultry farming.

Premix and feed recommendations

At Koudijs, we can produce organic certified premixes. Together with our special approach to stimulating remethylation of methionine for organic poultry production combined with our expertise in animal management and feed production, we can help you meet your production goals whilst complying with organic farming regulations.

Want to know more about our organic certified premixes?

About the author

Marnix van de Wetering

Specialist Poultry

Do you have any questions or would you like more information? Get in touch with Marnix.